VD Series Dry Running Rotary Vane Vacuum Pumps

Straightforward construction with single shaft direct drive makes for a robust, long-life rotary vane pump with low operation and maintenance costs.

VD Series Dry Running Rotary Vane Vacuum Pumps

- Details

- Specifications

- File

- spare part

Wordfik's oil-less rotary vane vacuum pumps are similar to other vane pumps. However, these pumps feature unique benefits you will not find with standard vacuum pumps. Their straightforward construction with single shaft direct drive makes for a robust, long-life rotary vane pump with low operation and maintenance costs.

Oil-less rotary vane vacuum pumps are positive-displacement pumps that feature sliding vanes in a rotor rotating within a cavity. Rotary vane pumps never experience internal metal-to-metal contact, so they are able to self-compensate for wear.

They have lower maintenance requirements and maintain peak performance longer than other types of vacuum pumps. Wordfik’s oil-less rotary vane vacuum pumps are an excellent choice for medium or variable vacuum range applications.

|

|

|

|

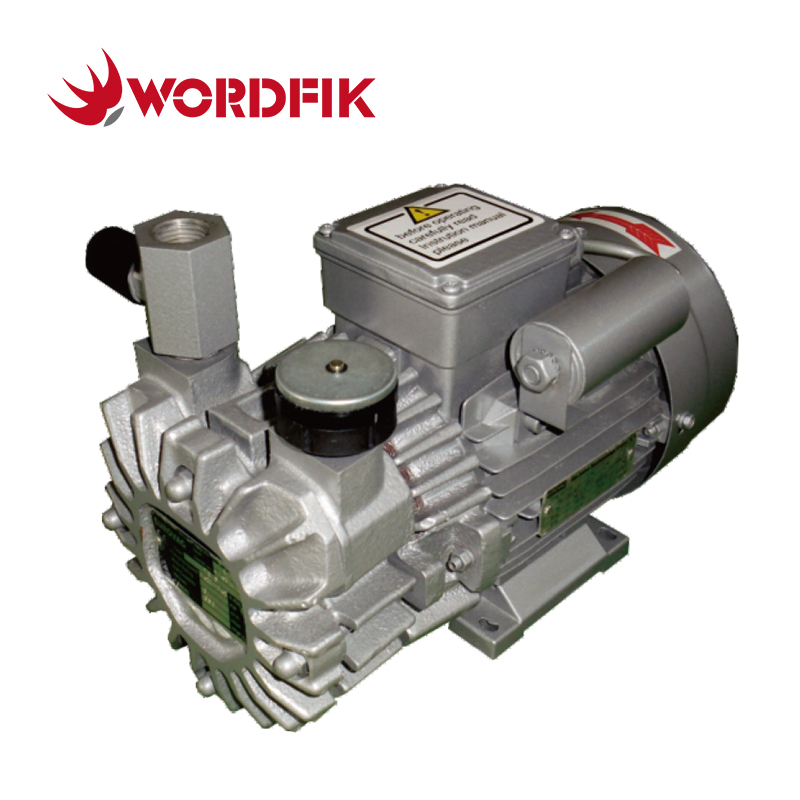

| VD-8 | VD-10~40 | VD-60~160 | VD-200~400 |

| Product models | Frequency | Pumping Speed | Ultimate Pressure | Motor Power | Motor Voltage (V) | Nominal Motor Speed (rpm) | Noise Level | Inlet Connection | Weight | Dimensions | ||

| (Hz) | (m³/h) | (mbar) | (kW) | 3ph | 1ph | 3ph | 1ph | (db) | (in) | (kg) | (mm) | |

| VD-8 | 50 Hz | 8 m³/h | 150 mbar | 0.37 kW | 175-260/300-450 V | 220-240 V | 1420 rpm | 1380 rpm | 58(db) | G ⅜ | 13 kg | 314*140*177 |

| 60 Hz | 9.6 m³/h | 0.44 kW | 202-300/350-520 V | 220-240 V | 1700 rpm | 1630 rpm | 58(db) | |||||

| VD-10 | 50 Hz | 10 m³/h | 150 mbar | 0.37 kW | 175-260/300-450 V | 230V±10% | 1420 rpm | 60(db) | G ½ | 15 kg | 426*202*192 | |

| 60 Hz | 12 m³/h | 0.44 kW | 202-300/350-520 V | 230V±10% | 1700 rpm | 62(db) | ||||||

| VD-16 | 50 Hz | 16 m³/h | 150 mbar | 0.55 kW | 175-260/300-450 V | 230V±10% | 1420 rpm | 61(db) | G ½ | 22 kg | 454*225*208 | |

| 60 Hz | 19.2 m³/h | 0.56 kW | 202-300/350-520 V | 230V±10% | 1700 rpm | 64(db) | ||||||

| VD-25 | 50 Hz | 25 m³/h | 150 mbar | 0.75 kW | 190-255/330-440 V | 230V±10% | 1420 rpm | 62(db) | G ¾ | 28 kg | 502*252*292 | |

| 60 Hz | 30 m³/h | 0.9 kW | 190-290/330-500 V | 230V±10% | 1700 rpm | 67(db) | ||||||

| VD-40 | 50 Hz | 40 m³/h | 150 mbar | 1.25 kW | 190-255/330-440 V | 230V±10% | 1420 rpm | 67(db) | G ¾ | 39 kg | 570*270*292 | |

| 60 Hz | 48 m³/h | 1.5 kW | 190-290/330-500 V | 230V±10% | 1700 rpm | 72(db) | ||||||

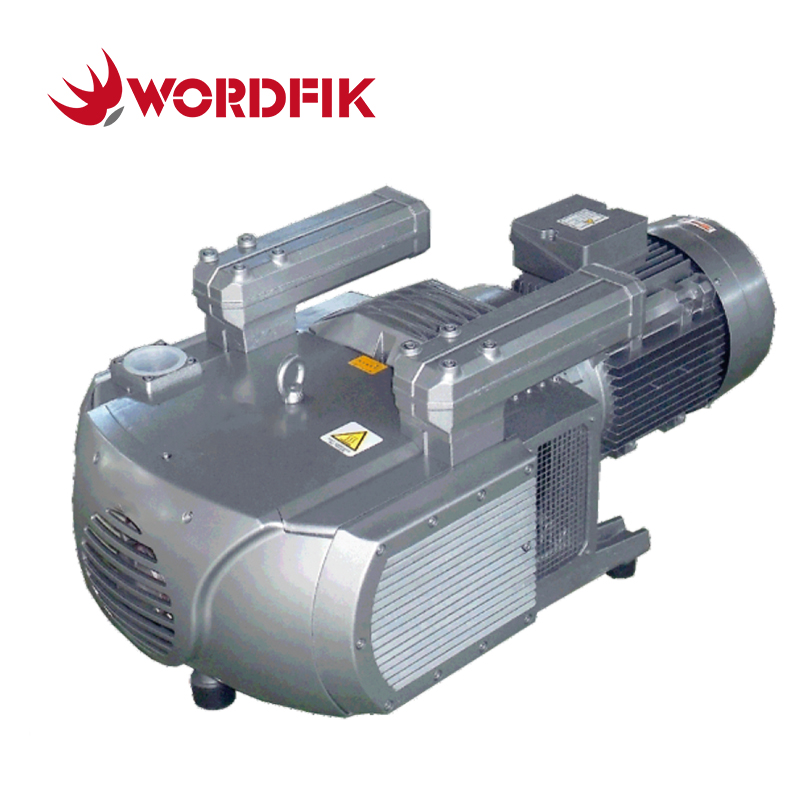

| VD-60 | 50 Hz | 60 m³/h | 150 mbar | 2.2 kW | 230/400V±10% | / | 1420 rpm | / | 71(db) | G 1 | 70 kg | 729*355*331 |

| 60 Hz | 72 m³/h | 2.6 kW | 230/400V±10% | / | 1700 rpm | / | 73(db) | |||||

| VD-80 | 50 Hz | 80 m³/h | 150 mbar | 2.2 kW | 230/400V±10% | / | 1420 rpm | / | 72(db) | G 1 | 70 kg | 731*355*331 |

| 60 Hz | 96 m³/h | 2.6 kW | 230/400V±10% | / | 1700 rpm | / | 75(db) | |||||

| VD-100 | 50 Hz | 100 m³/h | 150 mbar | 3.0 kW | 230/400V±10% | / | 1420 rpm | / | 75(db) | G 1½ | 105 kg | 870*470*382 |

| 60 Hz | 120 m³/h | 3.6 kW | 230/400V±10% | / | 1700 rpm | / | 77(db) | |||||

| VD-140 | 50 Hz | 140 m³/h | 150 mbar | 4.0 kW | 230/400V±10% | / | 1420 rpm | / | 76(db) | G 1½ | 115 kg | 870*470*382 |

| 60 Hz | 168 m³/h | 4.8 kW | 230/400V±10% | / | 1700 rpm | / | 79(db) | |||||

| VD-160 | 50 Hz | 160 m³/h | 150 mbar | 5.5 kW | 230/400V±10% | / | 1420 rpm | / | 76(db) | G 1½ | 126 kg | 926*470*382 |

| 60 Hz | 192 m³/h | 6.6 kW | 230/400V±10% | / | 1700 rpm | / | 79(db) | |||||

| VD-200 | 50 Hz | 178 m³/h | 200 mbar | 4.0 kW | / | / | 960 rpm | / | 75(db) | G 2 & G 2½ | 258 kg | 1092*612*494 |

| 60 Hz | 218 m³/h | 4.8 kW | / | / | 1150 rpm | / | 77(db) | |||||

| VD-250 | 50 Hz | 250 m³/h | 200 mbar | 5.5 kW | / | / | 960 rpm | / | 81(db) | G 2 & G 2½ | 280 kg | 1092*612*494 |

| 60 Hz | 300 m³/h | 6.6 kW | / | / | 1150 rpm | / | 81(db) | |||||

| VD-360 | 50 Hz | 351 m³/h | 250 mbar | 11 kW | / | / | 1430 rpm | / | 80.5(db) | G 2 & G 2½ | 312 kg | 1092*612*494 |

| / | / | / | / | / | / | / | / | |||||

| VD-400 | 50 Hz | 400 m³/h | 250 mbar | 7.8 kW | / | / | 960 rpm | / | 81(db) | G 2½ & G 3 | 320 kg | 1260*612*550 |

| 60 Hz | 401 m³/h | 9.3 kW | / | / | 1150 rpm | / | / | |||||

| Application And Industrials Uses |

As a leader in the field of suction and blast air we offer complete solutions driven by your individual needs. Our dry-running rotary vane vacuum pumps are the ideal solution for many industrial applications, such as packaging applications in the food and non-food sectors, suction applications in the medical industry, thermoforming of plastic parts, pick & place applications, and water treatment in the environment protection industry. You can check below to see the application of Wordfik's dry rotary vane vacuum pumps in your industry. |

| Application : |

| Degassing |

| Vacuum pumps are the preferred solution for removing gases, air, moisture, and vapor from processed materials like plastics, ceramic, and pasta to improve the finished product quality. |

| Evacuation |

| From food processing and packaging, to thermoforming and manufacturing, the removal of air or gas from a given space is one of the most wide ranging applications of vacuum pumps and systems. |

| Extracting |

| Vacuum pumps and blowers are used for a wide range of applications that require the removal of fluids, waste, air, as well as various other materials. |

| Pick & Place |

| Many modern production processes require the use of vacuum to transport, lift, and place goods and materials, including feeders for printing, secondary packaging, and other automatic loaders. |

| Pneumatic Conveying |

| Low pressure and vacuum solutions are perfect for transferring powders, granules, flakes, and other small, dry, low bulk density products. |

| Vacuum Fixing |

| Vacuum pumps and vacuum systems from Wordfik are the ideal solution for holding goods and components in place during production, processing, and packaging. |

| Industrials : |

| CNC Routing - Woodworking Industry |

| Vacuum pumps from Wordfik, provide the strong vacuum hold down that is imperative for keeping parts in place and reducing scrap. |

| Construction Industry |

| Perfect for turning air into power, our vacuum pumps and compressors are built to withstand the high demands of working on construction sites. |

| Energy |

| Wordfik vacuum pumps follow the trend to new technologies and are an important and efficient component of stationary fuel cells, and battery production, among others. |

| Environmental Industry |

| Vacuum pumps and compressors from Wordfik are the preferred solution for sparging, wastewater treatment, and aeration. |

| General Mechanical Engineering |

| Wordfik provides customized vacuum pump and compressor solutions for numerous mechanical engineering applications across the world, such as conveying, transporting, fixing, lifting, handling, drying, cooling and many more. |

| Laser Industry |

| Blower components are assembled, following a multi-stage cleaning process – under clean room conditions, and deployed as extraction or recirculation blowers for noble gases like helium or to convey inert gases, for example. |

| Medical Industry |

| Our highly reliable vacuum pumps are found in many central medical/surgical vacuum systems and medical devices. |

| Plastics Industry |

| From the production of new plastic components to the resource-friendly recycling of PET – vacuum pumps/systems and compressors from Wordfik are involved in the process. |

| Maple Sugar Extraction |

| Wordfik vacuum pumps and accessories are designed to be sturdy and durable with low maintenance and operating costs, and are perfectly suited for use in maple sugar extraction. |

| Primary Packaging and Food Processing |

| Whether you have an inline tray sealer, chamber machine, rotary chamber machine, tumbler or massager our robust vacuum pumps keep your machine running. |

| Printing and Paper Industry |

| Whether you need an individual unit or a system, Wordfik's vacuum pumps, compressors for blast air, and combined pressure/vacuum pumps are made for the various processes used in the printing and paper industry - from the pre-press stage, to sheet fed and digital presses, to the post-press. |

| Secondary Packaging Industry |

| Tray formers, carton and case erectors, baggers, cappers and fillers, inserters and palletizers represent just some of the numerous machines where you can find Becker Pumps. |

| Thermoforming |

| From clamshells, to blisters and trays we offer several vacuum pump technologies to meet your individual needs. |

| Electronics Industry |

| Vacuum pumps from Wordfik are perfectly suited for the absolute precision, low pulsation and vibration, and integrability challenges associated with the manufacturing, processing and testing of all types of electronic components. |

| Product models | Frequency | Pumping Speed | Ultimate Pressure | Motor Power | Motor Voltage (V) | Nominal Motor Speed (rpm) | Noise Level | Inlet Connection | Weight | Dimensions | ||

| (Hz) | (m³/h) | (mbar) | (kW) | 3ph | 1ph | 3ph | 1ph | (db) | (in) | (kg) | (mm) | |

| VD-8 | 50 Hz | 8 m³/h | 150 mbar | 0.37 kW | 175-260/300-450 V | 220-240 V | 1420 rpm | 1380 rpm | 58(db) | G ⅜ | 13 kg | 314*140*177 |

| 60 Hz | 9.6 m³/h | 0.44 kW | 202-300/350-520 V | 220-240 V | 1700 rpm | 1630 rpm | 58(db) | |||||

| VD-10 | 50 Hz | 10 m³/h | 150 mbar | 0.37 kW | 175-260/300-450 V | 230V±10% | 1420 rpm | 60(db) | G ½ | 15 kg | 426*202*192 | |

| 60 Hz | 12 m³/h | 0.44 kW | 202-300/350-520 V | 230V±10% | 1700 rpm | 62(db) | ||||||

| VD-16 | 50 Hz | 16 m³/h | 150 mbar | 0.55 kW | 175-260/300-450 V | 230V±10% | 1420 rpm | 61(db) | G ½ | 22 kg | 454*225*208 | |

| 60 Hz | 19.2 m³/h | 0.56 kW | 202-300/350-520 V | 230V±10% | 1700 rpm | 64(db) | ||||||

| VD-25 | 50 Hz | 25 m³/h | 150 mbar | 0.75 kW | 190-255/330-440 V | 230V±10% | 1420 rpm | 62(db) | G ¾ | 28 kg | 502*252*292 | |

| 60 Hz | 30 m³/h | 0.9 kW | 190-290/330-500 V | 230V±10% | 1700 rpm | 67(db) | ||||||

| VD-40 | 50 Hz | 40 m³/h | 150 mbar | 1.25 kW | 190-255/330-440 V | 230V±10% | 1420 rpm | 67(db) | G ¾ | 39 kg | 570*270*292 | |

| 60 Hz | 48 m³/h | 1.5 kW | 190-290/330-500 V | 230V±10% | 1700 rpm | 72(db) | ||||||

| VD-60 | 50 Hz | 60 m³/h | 150 mbar | 2.2 kW | 230/400V±10% | / | 1420 rpm | / | 71(db) | G 1 | 70 kg | 729*355*331 |

| 60 Hz | 72 m³/h | 2.6 kW | 230/400V±10% | / | 1700 rpm | / | 73(db) | |||||

| VD-80 | 50 Hz | 80 m³/h | 150 mbar | 2.2 kW | 230/400V±10% | / | 1420 rpm | / | 72(db) | G 1 | 70 kg | 731*355*331 |

| 60 Hz | 96 m³/h | 2.6 kW | 230/400V±10% | / | 1700 rpm | / | 75(db) | |||||

| VD-100 | 50 Hz | 100 m³/h | 150 mbar | 3.0 kW | 230/400V±10% | / | 1420 rpm | / | 75(db) | G 1½ | 105 kg | 870*470*382 |

| 60 Hz | 120 m³/h | 3.6 kW | 230/400V±10% | / | 1700 rpm | / | 77(db) | |||||

| VD-140 | 50 Hz | 140 m³/h | 150 mbar | 4.0 kW | 230/400V±10% | / | 1420 rpm | / | 76(db) | G 1½ | 115 kg | 870*470*382 |

| 60 Hz | 168 m³/h | 4.8 kW | 230/400V±10% | / | 1700 rpm | / | 79(db) | |||||

| VD-160 | 50 Hz | 160 m³/h | 150 mbar | 5.5 kW | 230/400V±10% | / | 1420 rpm | / | 76(db) | G 1½ | 126 kg | 926*470*382 |

| 60 Hz | 192 m³/h | 6.6 kW | 230/400V±10% | / | 1700 rpm | / | 79(db) | |||||

| VD-200 | 50 Hz | 178 m³/h | 200 mbar | 4.0 kW | / | / | 960 rpm | / | 75(db) | G 2 & G 2½ | 258 kg | 1092*612*494 |

| 60 Hz | 218 m³/h | 4.8 kW | / | / | 1150 rpm | / | 77(db) | |||||

| VD-250 | 50 Hz | 250 m³/h | 200 mbar | 5.5 kW | / | / | 960 rpm | / | 81(db) | G 2 & G 2½ | 280 kg | 1092*612*494 |

| 60 Hz | 300 m³/h | 6.6 kW | / | / | 1150 rpm | / | 81(db) | |||||

| VD-360 | 50 Hz | 351 m³/h | 250 mbar | 11 kW | / | / | 1430 rpm | / | 80.5(db) | G 2 & G 2½ | 312 kg | 1092*612*494 |

| / | / | / | / | / | / | / | / | |||||

| VD-400 | 50 Hz | 400 m³/h | 250 mbar | 7.8 kW | / | / | 960 rpm | / | 81(db) | G 2½ & G 3 | 320 kg | 1260*612*550 |

| 60 Hz | 401 m³/h | 9.3 kW | / | / | 1150 rpm | / | / | |||||

- name number price

- Oil-Less Scroll Vacuum Pumps PLWX Series Oil-Less Scroll Vacuum Pumps PLWX Series 0

- Oil-Free Piston Vacuum Pumps VP Series 0

- PVT Series Pressure Compressor Vacuum Compound Pumps 0

- TD KTD Series Dry Running Rotary Vane Compressors 0

- VD Series Dry Running Rotary Vane Vacuum Pumps 0